Service Case

Engineering Overview

1、Project Name:Anhui Dongzhi Guangxin agrochemical Co., Ltd. Wharf Project

2. Project location: in Xiangyu Town, east of Chizhou City, Anhui Province, about 2.7km away from Wangdong bridge under construction in the upstream.

3. Project scale: the project includes three 1000 ton berths (taking into account 3000 ton berths). One liquid product berth and two bulk cargo berths are arranged from upstream to downstream. The liquid chemical berth is a floating berth of 1000 tons (taking into account 3000 tons), and the pontoon scale is 60 * 12 meters. A 49 * 4m steel approach bridge is set behind the pontoon to connect to the frame pier. A 346.38 * 4m pipeline is used to connect the frame pier and the plant area. A 20 * 12m substation is set behind the chemical berth for power supply of the chemical berth. The bulk and general cargo berths are two 1000 ton (taking into account 3000 ton) vertical berths. The dock platform is 233.2m long and 25m wide. One 23 * 14m substation platform is set at the rear of the wharf, and one transfer building is set on the wharf surface, 8 * 8m. The belt conveyor approach bridge, 3 ා and 4 ා approach bridges are set to connect with the land area of the plant area. The approach bridge dimensions are 414.8 * 4m, 362.2 * 9 and 386.3 * 9m respectively.

Participants:

Employer: Anhui Dongzhi Guangxin agrochemical Co., Ltd

Designer: Anhui Communications Survey and Design Institute Co., Ltd

Supervisor: Shanghai Haike Engineering Consulting Co., Ltd

Construction unit: China Railway Construction port and Waterway Bureau Group Co., Ltd

Quality supervision department: Chizhou construction engineering quality and Safety Supervision Bureau

Tested by: Ningbo Zhixin Testing Technology Co., Ltd

Overall drawing of the project

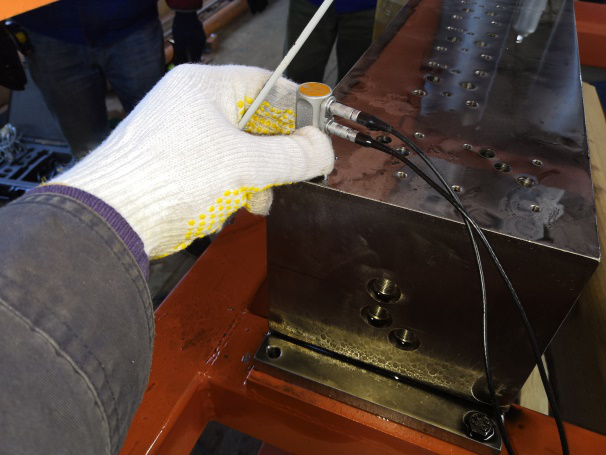

Actual inspection drawing

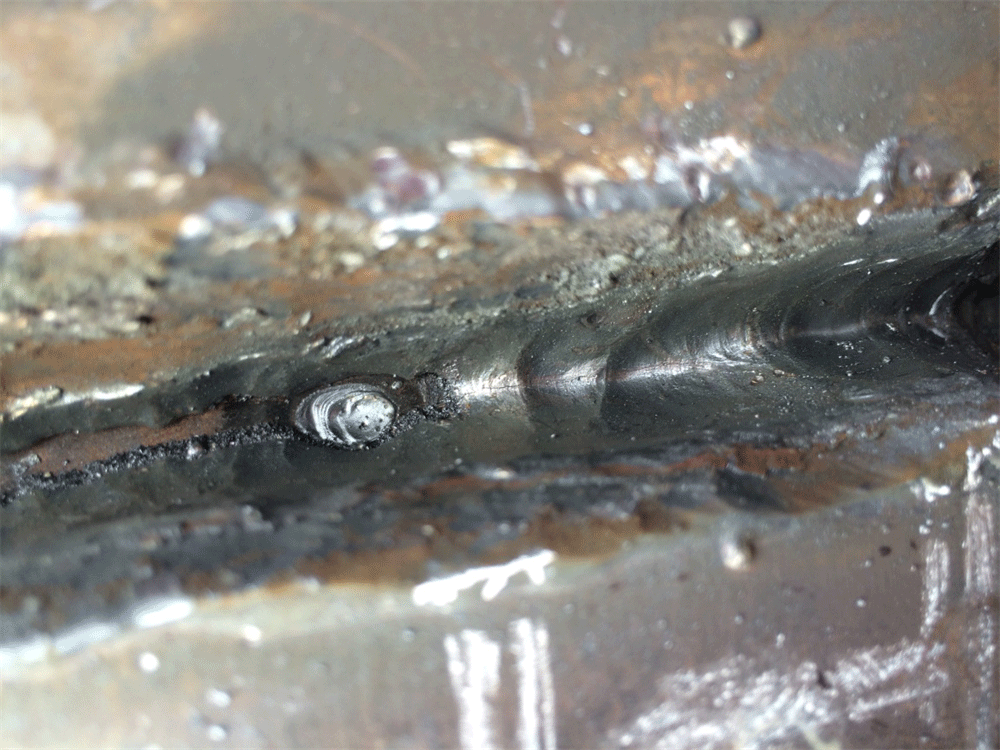

Detection defect

Root lack of fusion

Root lack of fusion

Other typical defects detected by ultrasound

Dissecting picture of crack found by ultrasonic inspection of armored tungsten alloy plate for tank